Recently, under the guidance of Mr. Gan Jinqiang and Prof. Ding Huafeng, Zhang Juncang, a graduate student, published the research result "Design of a pure rotation micropositioning stage with dual-range" in the TOP journal "Mechanism and Machine Theory" in the field of mechanical engineering. In this paper, aiming at the rotating operation in precision machinery, based on the design of compliant mechanism, the design of a pure rotation micropositioning stage with dual-range which can realize uncoupled pure rotation is proposed. The firs author is Zhang Juncang, a graduate student of Grade 2019, the corresponding author is Mr. Gan Jinqiang and the third author is Prof. Ding Huafeng.

In recent years, micro-electro-mechanical systems (MEMS), precision optics, biomedicine and other micro-operating fields are developing rapidly, and precision positioning platform, as a basic support technology in this field, has gradually become a research hotspot. The compliant mechanism is a new type of mechanism that transmits motion and force through the deformation of the compliant hinge. It adopts one-piece molding, with simple processing and installation process, no lubrication, no motion pair coordination and no friction, and is easy to realize high precision motion. The design of precision positioning platform based on the compliant mechanism has become an important part of the research of precision positioning system and is widely used in various precision operation fields such as scanning probe microscope, aerospace and biological micro manipulation. Domestic and foreign scholars have designed and studied a series of compliant precision positioning stages, and most of them are focused on the design of stages with translational degrees of freedom, and the design of stages containing rotational degrees of freedom accounts for a smaller proportion. The design of two-degree-of-freedom or multi-degree-of-freedom compliant precision positioning stages containing rotational degrees of freedom has become an important direction for research on precision positioning stage design. The design and research of compliant precision positioning stage with rotational degrees of freedom mainly focuses on the two rotational performances: large rotation angle and motion decoupling. As the range and resolution of the stage driver is fixed, when the output range of the stage is enlarged, it will lead to a decrease in the resolution of the stage. An effective way to solve this contradiction is to adopt the idea of "macro and micro combination" and build a dual-range rotation platform, nesting the large-range stage and the small-range stage in a way that takes into account the large range of the compliant precision positioning stage and the large range and high resolution of the relative high-resolution stage. In the design of the stage containing rotational degrees of freedom, the decoupling of rotational degrees of freedom is often difficult to achieve due to the complexity of the stage structure and degrees of freedom, which is a difficult point in the design of the compliant precision positioning stage.

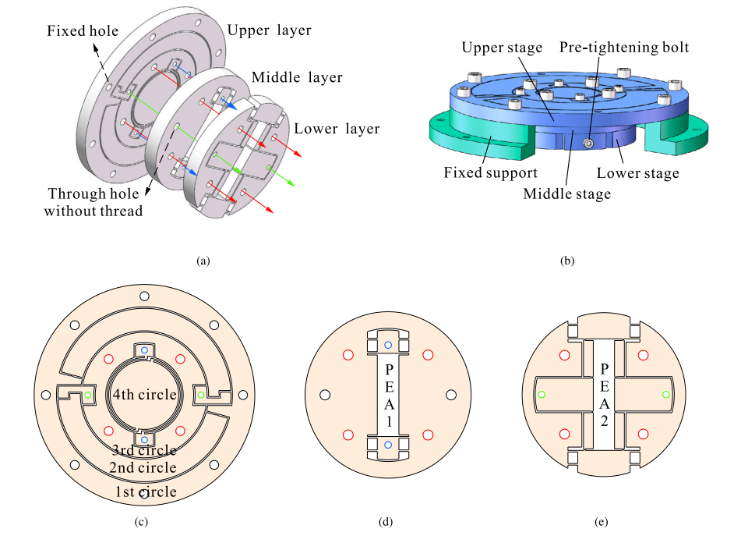

In response to the above problems, the paper proposes a dual-range precision positioning stage with no coupling and pure rotation based on the compliant mechanism. The design is derived from the crank slider mechanism, and the rotating mechanism of the stage consists of a softened crank slider mechanism. The stage rotation mechanism adopts inner and outer nesting design to achieve larger output range and higher displacement accuracy at the same time, the inner ring of the stage is a small range rotation mechanism and the outer ring is a large range rotation mechanism. The stage is designed in layers, consisting of upper and lower layers to obtain a more compact structural design. The upper layer is the rotating part, and the middle and lower layers are used as the driving part to drive the small range rotating mechanism and the large range rotating mechanism respectively. Through the inner and outer nesting design, upper and lower layered design and overall symmetrical arrangement, the coupling error of the designed stage reaches a negligible level, and the large and small ranges of the stage are [0 mrad, 17.40 mrad] and [0 mrad, 0.88 mrad] respectively, and the new dual-range precision positioning stage without coupling and pure rotation is realized.

The research results are supported by the National Natural Science Foundation of China.

Paper information

Title: Design of a pure rotation micropositioning stage with dual-range

Authors: Juncang Zhang, Jinqiang Gan∗, Huafeng Ding, Hai Li

Source: Mechanism and Machine Theory

DOI: 10.1016/j.mechmachtheory.2021.104631

Available online: 19 November 2021

Paper link: https://authors.elsevier.com/c/1e6T3,28z4Pz~9